Intelligent control continuous winding FRP sand-filled pipe production line

Category:

Key words:

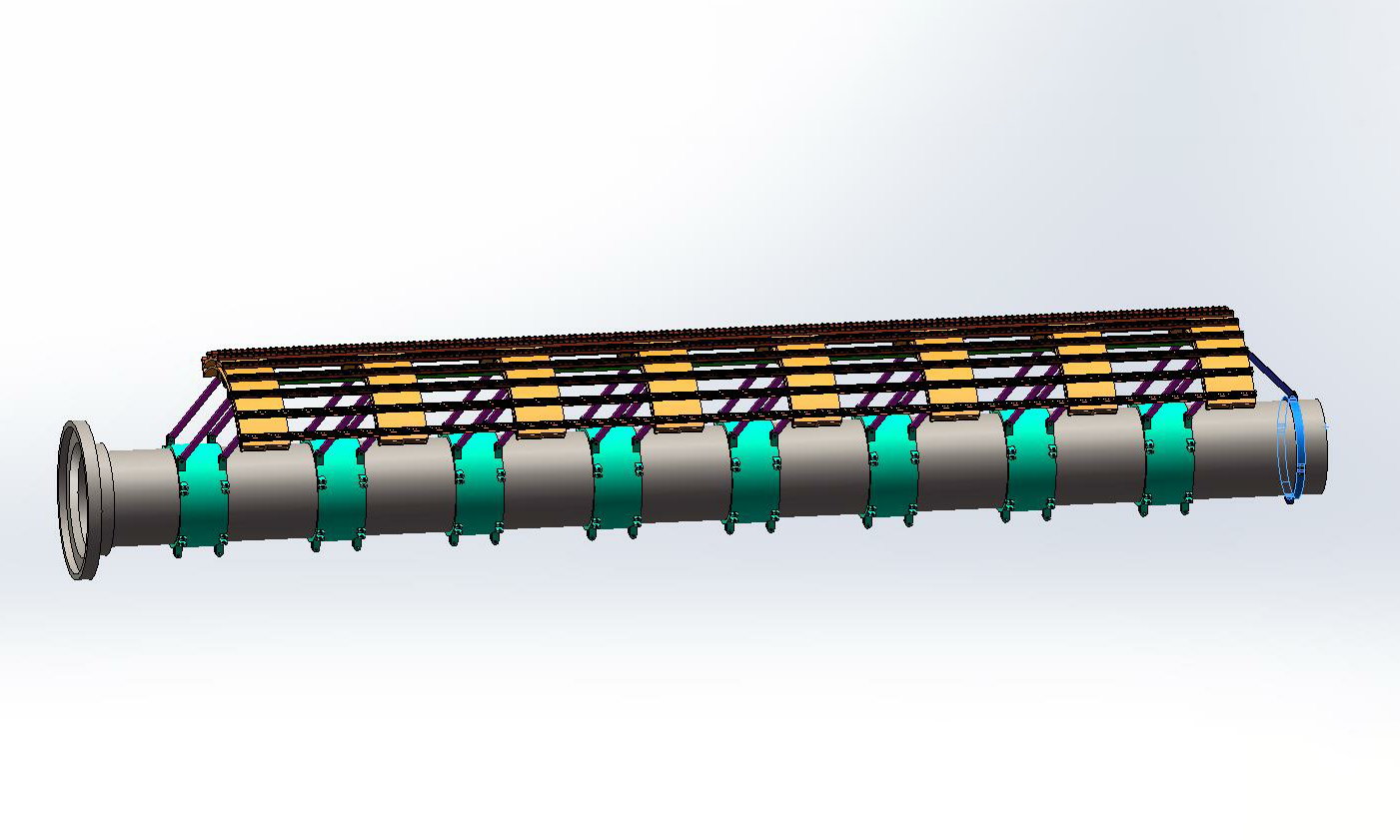

Intelligent control continuous winding FRP sand-filled pipe production line

Product Description

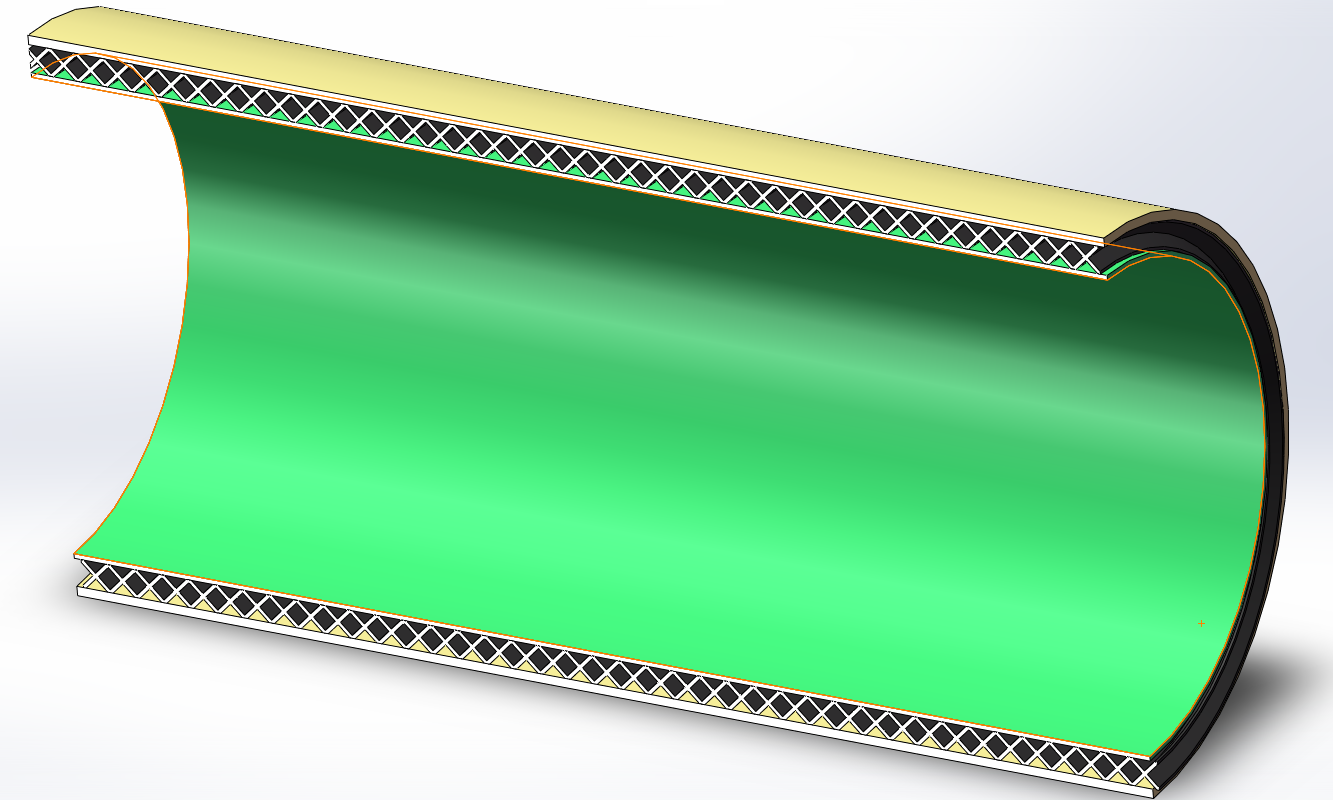

1. The continuous winding production process refers to the continuous laying of resin, continuous fiber, chopped fiber and quartz sand according to certain requirements on the continuous output mold, using the method of hoop laying, and cutting into a certain length of pipe after curing and molding. A fiberglass pipe forming process. Its typical features are a high degree of automation in the production process, continuous output of the pipeline and arbitrary cutting of the length of the pipeline, and the distribution of chopped fibers in the entire section of the tube wall structure to achieve an interlaced structure of the tube wall like 3D printing.

Innovative technology of continuous winding composite material pipeline in our institute

| ①Continuous production without steel strip |

②

⑤

⑨ |

| ② Variable Diameter Mold | |

| ③High-precision micro glue pump | |

| ④0 degree axial cloth yarn | |

| ⑤Sealed spray glue | |

| ⑥In-pipe tractor | |

| ⑦Continuous extrusion of sand layer | |

| ⑧Bamboo reinforced composite pipe | |

| ⑨Hollow wall structure tube | |

| ⑩thermoplastic composite pipe |

2. Advantages of continuous winding equipment: high degree of automation, full-process monitoring, stable and reliable product quality; fewer operators, high production efficiency, and low labor cost; strong pipe wall integrity, good mechanical properties, high pipe strength, and no layered cracking ;The production process is less and controllable, with good environmental protection performance and good working environment; the product length is not limited, and can be cut at will according to customer requirements; the sleeve is convenient to connect, and the hydraulic performance is good; the waste is reduced, the utilization rate of raw materials is improved, and the cost is reduced ; The industry threshold is high, there are few manufacturers, and the market is relatively standardized.

3. Important equipment parameters

1) Air source: 4m3, 10kg/cm2 air compressor with pressure tank and drying device

2) Power supply: three-phase 380V 50Hz not less than 450KW

3) Spindle speed: 0-20rpm

4) Production speed: 5 -40 (M/H) (The actual production speed is related to the pipeline process requirements, raw material properties and workers' operating proficiency)

5) Product specifications: DN300-4000.

6) Rigidity level: S=1250N/m2-300000N/m2

7) Pressure level: 0.1MPa-3.2MPa

8) Space occupied by the production line: 28×12×7.5M 9

) Workshop requirements: 70×40×7.5M

10) Single Shift workers: 4 people

4. The company's technical advantages

In recent years, we have advanced the core mold structure and core mold in the current continuous winding equipment production process through independent research and development, joint research, technological transformation, component improvement, and process improvement. Continuous improvement and optimization of core technologies such as method, sanding process, glue supply process, and curing process have completed a number of breakthrough innovations, expanded the application space of upgraded equipment, and always maintained the overall technological advancement of the equipment, making the product process more advanced. The performance is more stable, the operation is easier, the cost is further reduced, the requirements of the pipeline manufacturers are more satisfied, and the market competitiveness of the product is enhanced.

Our company's intelligent control continuous winding FRP pipe production equipment has the following advantages:

1. One-button start, with a higher degree of intelligence. According to the scientifically set production process sheet, the PLC control program has a good man-machine dialogue interface, which can accurately control various raw material distribution actions, and can realize arbitrary switching of products of different specifications; multi-point online monitoring feedback, deviation correction, abnormal warning, etc. Online action can correct operating parameters in time to ensure stable product quality; it can provide report data such as production speed, raw material consumption, and cost accounting in a timely manner; it has the functions of manual or automatic control switching, local and remote monitoring synchronous opening, and can realize mobile phones and computers. Remote terminal monitoring.

2. Glue supply is more accurate. The self-developed high-viscosity resin pump and CNC glue supply system can realize the unpowered glue mixing and precise supply of resin under constant temperature and pressure; the self-developed high-precision micro-flow glue pump and high-sensitivity one-way valve control technology can Guarantee the stable supply of curing agent and accelerator at the milligram level; the independent supply of curing agent and accelerator can precisely control the curing time by adjusting the distribution amount of accelerator to ensure stable product quality.

3. Adopt fully enclosed tubular glue distribution and magnetic suction glue pouring tank to realize stepless adjustment of glue width; system cleaning can be started with one button and completed in 10 seconds.

4. Fast curing speed and high production efficiency. Pipeline production speed can reach more than 800 meters per day.

5. The same machine can realize the production of high-strength and high-ring-rigidity FRP pipe jacking.

6. Adopt adjustable grid type sand distribution technology to ensure that the quartz sand is evenly dispersed.

7. Die radial stepless adjustment can meet the requirements of pipe wall thickness and ring stiffness of any specification.

Previous Page

Previous Page

Online

Message

If you have any suggestions or feedback about our company, please fill in the relevant information on this page and submit it. Our staff will contact you in a timely manner, or please call us directly.