-

-

Intelligent control continuous winding FRP sand-filled pipe production line

-

Intelligent control continuous winding FRP cable conduit production line

-

Intelligent control continuous winding bamboo reinforced composite pipe production line

-

Composite material electric (light) pole intelligent production line

-

Continuous glass fiber reinforced thermoplastic composite pipe production line

-

On-line continuous extrusion sand layer FRP pipe production line

-

-

-

ServiceStrong technical force, complete experimental conditions, advanced research and development equipment, and rich production experience

-

AboutThe Institute is engaged in the research and development of new technologies, new processes, new products and new equipment of composite materials, focusing on the manufacture of intelligent equipment of composite materials, and providing high-efficiency and low-cost overall solutions for composite material manufacturers.

-

NewsQinyang Composite Materials Research Institute welcomes industry colleagues to visit and guide. We are willing to work hand in hand with colleagues in the industry to seek common plans for the development of the composite industry and create a bright future for the development of the composite industry.

Lightweight hollow wall composite pipe production line

Category:

Key words:

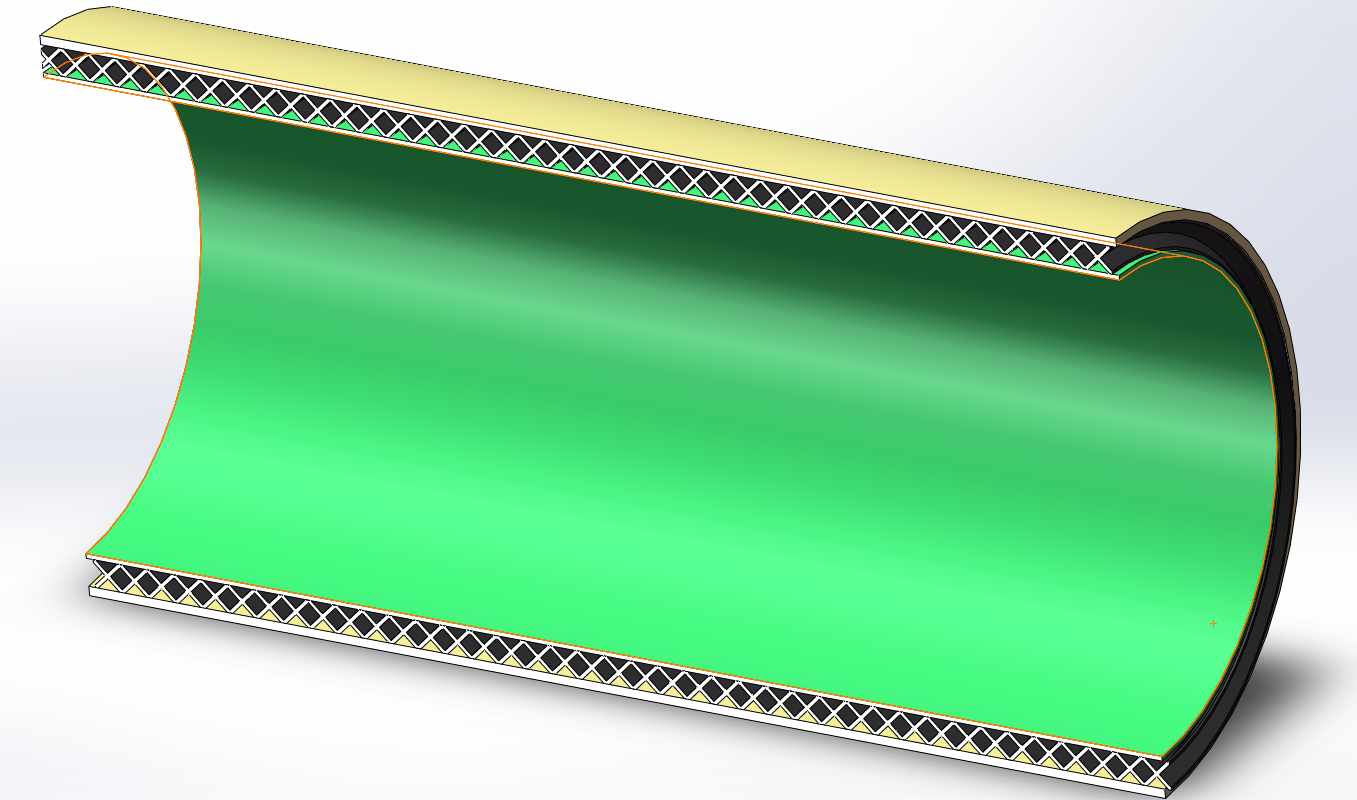

Lightweight hollow wall composite pipe production line

Product Description

(1) FRP sand-filled pipes currently used in the market have the following defects:

1. The structural strength is not enough, and the sand-filled layer is prone to cracking, damage and leakage, especially for reciprocating winding pipes.

2. The quartz sand layer requires more resin infiltration, which increases the amount of raw materials, thus increasing the cost of the pipeline;

3. Due to the large amount of quartz sand filled in the structural layer, the weight of the pipeline is increased, and the advantage of light weight of the FRP pipeline is reduced. The installation cost is high.

4. For the continuous winding process, the online continuous laying of chopped fibers, quartz sand and resin is difficult, the requirements for continuous winding equipment are high, and the pipeline manufacturing process is complicated, which restricts the improvement of production efficiency.

(2) The continuous winding hollow-wall FRP structural pipe is to add at least one hollow structural layer in the middle of the pipe wall. This hollow structural layer is realized by spirally winding evenly distributed circumferential vertical ribs of a certain height. A cavity structure is formed between the adjacent vertical ribs and the inner and outer solid wall cladding layers, which can increase the thickness of the pipe wall, provide higher structural strength, and reduce weight and cost.

(3) FRP pipes with hollow wall structure have the following advantages:

①High strength. The special cross-section design can significantly improve the structural strength of the pipeline, and it is especially easy to obtain FRP pipelines with high ring stiffness; the ring stiffness level can reach SN, which can meet the needs of various working conditions; ②Low cost

. While maintaining rigidity, it can effectively reduce the usage of raw materials, especially resin, thereby reducing the cost of pipelines;

③Light weight. Because the pipeline structure is hollow, the weight of the pipeline is significantly reduced, the density of the pipe wall is small, and the meter weight of the pipe is about 1/10 of the cement pipe of the same specification. The transportation and installation are extremely convenient, and no large machinery is required for hoisting and assembly. The advantage is especially obvious in the complex and harsh environment of pipeline operation. It can reduce labor intensity, shorten construction period, reduce pipeline shipment and installation costs, and significantly improve overall benefits compared with traditional pipes;

④High production efficiency. It can further increase the pipeline production speed and reduce labor costs;

⑤The production device is simple. In particular, the steel belt circulation mechanism, the steel belt correction mechanism, the steel belt rotation mechanism and the release film are omitted, which can reduce equipment operating costs and improve production efficiency, and has good practicability.

(4) Key technologies

On-line forming of cavity vertical ribs

Cavity cladding material

Treatment of the upper and lower layers of vertical ribs Bonding interface treatment of

vertical ribs Curing time control

End cavity plugging

(5) This technology is innovative and advanced. At present, there is no mature continuous winding hollow-wall FRP structural pipe technology and equipment that can be used in actual production at home and abroad. Our institute has obtained more than 10 related invention patents and utility model patents.

Next Page

Online

Message

If you have any suggestions or feedback about our company, please fill in the relevant information on this page and submit it. Our staff will contact you in a timely manner, or please call us directly.

Research Institute is engaged in the research and development of new technologies, new processes, new products and new equipment of composite materials, focusing on the manufacture of intelligent equipment of composite materials, and providing high-efficiency and low-cost overall solutions for the "one-to-one" of composite material manufacturers

Complete equipment

Supporting equipment

Copyright©2023 Qinyang Composite Materials Research Institute Co., Ltd. www.300.cn SEO This website supports ipv6

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.